LONG RANGE ULTRASONIC INSPECTION OF PIPING

guided wave Ultrasound (GWT)

Our Advanced NDT Group utilizes Guided Wave Testing (GWT) to remotely analyze assets for corrosion and flaws over long distances, without the need for shut-down. GWT can be used for evaluation of corrosion damage and other defects in oil and gas pipelines, chiller systems, fire repression piping, and solid rods.

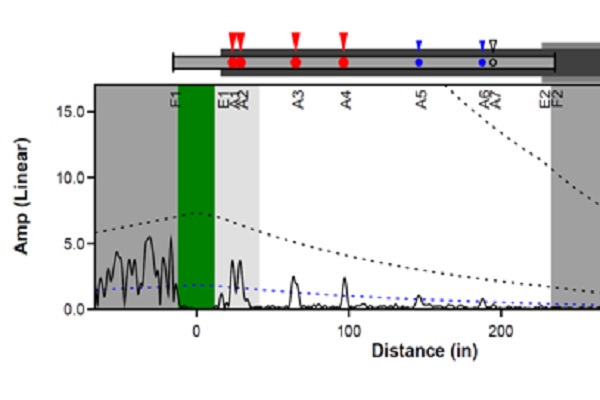

GWT employs mechanical stress waves that propagate along an elongated structure, while guided by its boundaries. This allows the waves to travel a long distance with little loss in energy. Indications create reflections, which are graphed for further analysis by our certified inspectors.

Our portable field equipment is composed of three primary components, the transducer ring, the Wavemaker™ G4 instrument, and the controlling computer.

Transducer rings are attached to the outside of the structure, which couple piezoelectric transducer elements to the pipe/rod being inspected. Long lengths of pipe/rod are examined from one location, which allows difficult to inspect areas, such as buried or insulated piping, to be screened with ease and minimal surface preparation. Contact us today to discuss your project or to schedule an inspection.

APPLICATIONS

Buried pipe

Insulated pipe up to 340°C

Boiler tubes

Road and rail crossings

CAPABILITIES

Inspection of 100% of pipe/rod volume

Rapid identification of corrosion damage in buried or covered structures

Ability to detect corrosion and other defects

Monitoring for corrosion over time

Collect corrosion data at difficult to access areas

Portable equipment

SPECIFICATIONS

ASTM E 2775

SAMPLE REQUIREMENTS

Sample Diameter Sizes – 1″ to 40+” diameter

Removal of about 1 meter of insulation

Surface preparation to scrape off loose paint or scale